What is Foam Roofing?

Spray polyurethane foam, commonly referred to as SPF and used in many San Jose commercial roofing projects, is a spray-applied insulating foam plastic. The two chemical components are combined as they pass through the spray gun and contact the substrate as a liquid. As the two components chemically react they expand in volume by 20 times and form a strong, rigid material with a density of 2.5 to 3.0 pounds per cubic foot and a compressive strength of 40 to 50 pound per square inch.

Specialized equipment is used to apply the SPF and proper technical training is essential to obtain the best results for any roof in Silicon Valley, San Jose, the East Bay and over the entire Central and Northern California area.

When used as a roofing material in a San Jose Commercial roofing project, SPF provides:

- A waterproof roofing membrane

- Added insulation

- An air barrier

- Sound attenuation

- Structural properties

- Fire retardancy

- Light weight

- Renewability

- Sustainability

- Condensation control

- Affordability

SPF is the king of roof building material multi-tasking. In insulation, it can provide high levels of R-value, while providing air barriers and assistance in moisture control in buildings. In roofing, it insulates and eliminates thermal bridging through fasteners and gaps in insulation boards.

SPF roofing is “green” roofing, renewable and sustainable. With proper maintenance and recoating at 20 year intervals an SPF roof will last the life of the building. Bright white topcoat meets “Cool Roof,” Energy Star, and LEED Certification requirements.

Insulation

Spray Foam Insulation

There is no better insulating material to seal a building from air and moisture intrusion, save on costly utility bills, and strengthen your roof than Spray Foam Insulation.

Benefits of Spray Foam Insulation

- Stops air and moisture infiltration

- Makes a building more comfortable

- Saves on energy costs

- Adds strength to the building structure

- It is permanent and will not sag

- Keeps dust and pollen out

- Reduces capacity requirements, maintenance, and wear of HVAC equipment

High R-Value

Sprayed polyurethane foam has an aged R-value of approximately 6.4 per 1-inch thickness (depending on the particular formulation and application, higher values can be achieved), enabling it to provide more thermal resistance with less material than any other type of commercial insulation material. SPF systems are frequently used to insulate and protect a wide variety of residential, commercial, and industrial buildings.

Energy and utility savings

Central Coating Co utilizes a newly developed energy calculator, the Energy Performance Matrix Toolbox (EPMT) to predict the energy savings from insulating with sprayed polyurethane foam.

Prevents Air, Moisture and Gas Infiltration

Because SPF seals all joints and gaps found in the building envelope, it stops air infiltration which can result in a significant part of a building’s total energy loss.

Cool Roof

A Cool Roof is a roof that has a light colored coating which reflects the sun’s heat and UV rays. When combined with SPF insulation these materials improve the building’s energy performance. Cool Roofs can reduce air conditioning costs, reduce smog, and help the environment. Roof surface temperatures can be reduced up to 70º F when compared to a dark colored roof. Air infiltration will be eliminated and electric bills can be significantly reduced.

Re-Coating

With proper maintenance and periodic recoating an SPF roof will last the life of a building. An important advantage of an SPF roof is that it can be renewed by recoating at the end of its “design life” instead of being completely replaced like other roof systems. Design life refers to the period of time between the roof installation and the first recoat. The Design Life of Central Coating roofs is at least 20 to 25 years meaning that your foam roof will provide 20 to 25 years of service before the first recoat is required. The Design Life can be extended by increasing the thickness of the acrylic coating system during initial roof installation. The addition of roofing granules in the top pass of the coating system further enhances the life of the coating system.

The acrylic coating which protects the foam from UV radiation is the wearing component of the roof system. When the acrylic coating begins to wear thin it will need to be recoated but the foam component of the roof system does not need to be removed or replaced.

How we recoat your roof

- Powerwash the roof to remove dirt, debris, and oxidized coating.

- Repair any damage that has occurred over the life of the roof.

- Update any details to current installation standards.

- Seal any new penetrations to current standards.

- Inspect all drains, flashings, edge metal, etc. Replace or repair as required.

- Install an additional coat of acrylic coating.

- Install granules into the coating system.

- Reissue leak free warranty and maintenance agreement

Central Coating maintains relationships with long-term customers and will recommend that recoats be performed when necessary. CCC can also service foam roofs installed by other contractors.

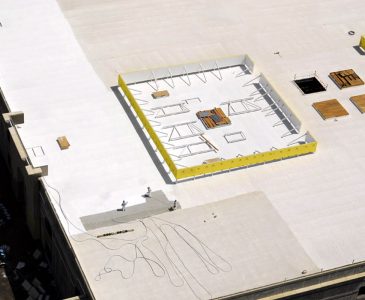

New Construction

SPF roofing is “green” roofing, renewable and sustainable. With proper maintenance and recoating at 20 to 25 year intervals an SPF roof will last the life of the building. Bright white topcoat meets “Cool Roof,” Energy Star, and LEED Certification requirements.

Architects, general contractors, and building owners are choosing SPF roofs as the preferred solution for new construction, and the advantages over built-up asphalt and single-ply rubber roofs are compelling.

- Superior waterproofing—provides a one-inch thick or greater waterproof membrane

- Seamless Application—eliminates the most common failure point in other roof systems

- Superior Insulation—choose the insulation value to meet your needs. A one-inch thick foam roof delivers an insulation value of R-6.4. Thicker roofs provide R-19, R-30, and up to R-60 in freezer applications.

- SPF is the roof membrane and the insulation. Having the insulation on the outside of the building provides superior insulation performance.

- SPF is often installed over insulation boards, improving their insulation efficiency by eliminating the thermal shorts attributable to fasteners and gaps.

- Ease of application. The self flashing nature of SPF allows most HVAC curbs and pipe penetrations to be sealed without the complicated sheet metal flashings required by other types of roofing. By fully adhering to penetrations SPF eliminates air infiltration and water leaks.

- SPF can be installed to form slope to drain. By installing the SPF in tapered passes a flat roof deck can be sloped at ¼ inch per foot (or whatever slope is required). The added foam thickness provides added insulation. In these cases the SPF roof provides the roof slope, the insulation, and the roof membrane. That’s three scopes of work being completed by one trade at a substantial cost savings.

SPF Roofing is Compatible With All Types of Roof Deck Construction

- Steel Deck

- Wood Deck

- Concrete Deck

Re-Roof

The advantages for re-roofing with SPF are compelling:

- Your new SPF roof can be installed without removing the existing built up roof. Tearing off a roof is costly and can be a large inconvenience to a building’s tenants due to noise and dust falling from the roof deck. Also, foaming over an existing roof reduces liability for all parties as the roof is never “open” and subject to catastrophic water damage.

- The SPF roof will be the last roof ever installed on the building. With proper maintenance and recoating at 20 to 25 year intervals the SPF roof should last the life of the building. This reduces a building’s life-cycle costs and is also environmentally friendly. By breaking the cycle of tear-off and re-roof the burden on landfills due to roofing debris is eliminated.

- Due to the sprayed in place nature of SPF it can be installed in varying thickness to promote drainage, fill in low areas and eliminate ponding. Ponding is the bane of all roofing systems as it causes rapid deterioration and leads to premature failure. Ponding water is heavy which causes deck deflection which causes even more ponding. Re-roofing with SPF stops this snow ball effect.

- CCC has developed comprehensive installation guidelines as well as over 140 installation details. These are used by CCC’s estimators to design your new roof and are incorporated into the contract documents. They are then used by CCC’s crews to ensure that your new roof is installed as specified and satisfies CCC’s quality control requirements as well as the client’s expectations.

- As part of the re-roofing process CCC will replace all edge metal andwill upgrade mechanical equipment supports to work with SPF roofing. Wood pipe support blocks are replaced with fiberglass reinforced polyester (FRP) blocks. The end product of this work is a roof system that is isolated from the other components of the roof. For example an HVAC unit can be replaced without disturbing or damaging the roof. A deteriorating wood sightscreen will not lead to roof leaks.

- In most cases CCC can re-roof a building without removing the HVAC equipment or disrupting the tenant’s operations. While there is a small amount of noise associated with the preparation work, the impact on a building’s tenant is much less than the impact caused by other types of re-roofing.

- Let us evaluate your roof to see if it’s a candidate for an ElectroRoof® installation. With a photovoltaic array you can convert an expense to a revenue producer.